Radon manometers are commonly used to measure low differential pressures in various industrial applications. They consist of a U-shaped tube filled with a fluid that determines the pressure difference across two points. However, many people are not aware of the fluid used in radon manometers and their properties. This comprehensive guide will enlighten you on “What Is the Fluid in a Radon Manometer” and everything you need to know about it.

Table of Contents

What Is the Fluid in a Radon Manometer?

Understanding Radon

Radon is a colorless, odorless, and tasteless radioactive gas that occurs naturally in the environment. It is the byproduct of decaying uranium and radium in soil, rocks, and water. However, due to the potential health risks of radon, monitoring and measuring its levels in homes and buildings is crucial. So, one of the devices commonly used for this purpose is a radon manometer. This article will help you explore the ultimate question: What Is the Fluid in a Radon Manometer? We will also help you understand its significance in measuring radon levels accurately.

Understanding Radon Manometers

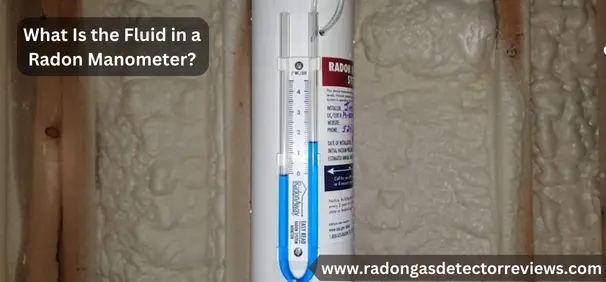

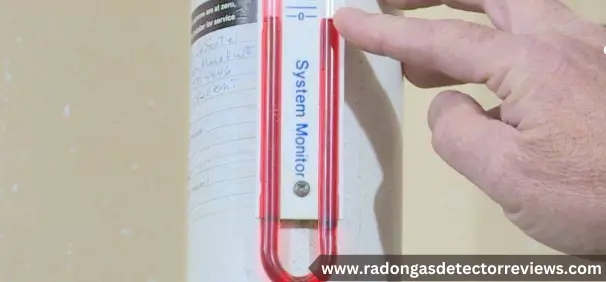

As we mentioned earlier, Radon Manometer is a device that measures the pressure difference between two points in a closed system. It works on the principle of hydrostatic equilibrium to gauge pressure.

The working principle of a radon manometer depends on the fact that the two arms of the U-Tube (half full of liquid) will balance each other when both are exposed to the same pressure.

Adding or removing fluid from one arm can alter the equilibrium to measure the differential pressure.

Besides, the manometer does not read the same on both sides. If that happens, it means the fan isn’t working, or the flue is plugged. The readings are also an important representation of the system’s performance.

So, radon manometers are used for monitoring and controlling low-pressure systems, vacuum systems, and cleanrooms.

Understanding Fluids in Radon Manometers

Coming to the final question: What is the fluid in a radon manometer? The fluid used in a radon manometer is typically a colored liquid, such as mercury, or a liquid with a high boiling point, like oil or silicone.

In older models, mercury was commonly used due to its distinct visibility and high density. However, alternative fluids have gained popularity today due to health and environmental concerns associated with mercury.

Oil-based or silicone-based fluids are frequently used as replacements for mercury. These fluids offer several advantages, such as being non-toxic, non-hazardous, and non-volatile. They are also less susceptible to temperature fluctuations, ensuring accurate temperature readings.

Different Types of Fluids Used In Radon Manometers

What is the fluid in a radon manometer? There are three types of radon manometers: U-shaped, Inverted-U, and Inclined Tube. The U-tube manometer is the most commonly used because of its simplicity and easy maintenance.

Besides, the three common fluid types that make the base for these manometers include:

Mercury-Based

Mercury-based radon manometers are the most common for their high-density nature and ability to measure even minimal changes in pressure. They are extremely accurate and reliable. However, due to the toxicity of mercury, their use is being phased out, and they are being replaced with safer alternatives.

Glycerol-Based

Glycerol-based radon manometers are a safer and more environmentally-friendly alternative to mercury-based manometers. Glycerol is a viscous, clear, and odorless liquid that does not evaporate, making it ideal for use in low-pressure settings. These are less toxic than mercury but also a little inaccurate in comparison.

Alcohol-Based

Alcohol-based radon manometers use a mixture of isopropyl alcohol and water, an alternative to both mercury and glycerol manometers. They have lower toxicity and can measure larger pressure ranges. However, they are less accurate than mercury or glycerol-based manometers and may require frequent calibration.

Remember, different fluids have varying properties, such as viscosity, density, and surface tension. These can affect the sensitivity and accuracy of the manometer. Therefore, the right choice of fluid depends on the application, any specific requirements, and the level of accuracy required.

Significance of Fluid Choice

The choice of fluid in a radon manometer is critical for accurately measuring pressure differentials. It must possess specific properties to ensure reliable readings and ease of use.

Here are some key factors that must be considered:

Compatibility

The fluid should be compatible with the materials used in the manometer construction to avoid any chemical reactions or damage to the device.

Density

The fluid should have a suitable density to indicate pressure variations clearly. A denser fluid will result in a more noticeable shift in the fluid column, making it easier to read.

Stability

The fluid should be stable and not prone to evaporation or degradation over time. This ensures the longevity of the manometer and maintains accuracy in pressure measurements.

Visibility

The fluid should be easily visible to allow users to observe pressure variations. A brightly colored liquid or a fluid with a contrasting color to the background helps detect minute changes in pressure.

Precautions While Handling Radon Manometers

What is the fluid in a radon manometer? Any of the above. But what is more important? Proper handling of these devices.

So, when you are using radon manometers, it is crucial to exercise care to prevent breakage, physical injury, and possible environmental contamination. Moreover, the manometer should be insulated in order to avoid the risk of breakage or electrocution.

Broken manometers should be handled with utmost caution to prevent mercury exposure, which can be highly toxic. In addition, make sure that it does not tilt to avoid the fluid from spilling.

The fluid contains hazardous matter, and contact with it may lead to serious health complications. Hence, the disposal of broken manometers and used fluids should follow the regulations and guidelines for handling hazardous waste. Safeguarding oneself by using protective gear such as gloves and a facemask while handling the liquid is also essential.

Handling a radon manometer is not a task to be taken lightly. Ensuring safety and protection while handling, disposing, or maintaining the device and fluid is paramount. Hence, everybody using or handling a radon manometer should take the necessary precautions to guarantee personal and communal safety.

Conclusion

A radon manometer is an essential tool for monitoring and measuring radon gas levels. Understanding the fluid in a radon manometer is important in selecting the right type of fluid for an application. It ensures safety and reduces the risk of environmental contamination. In addition, these fluids provide visibility, stability, and compatibility necessary for accurate and reliable measurements proper handling measures, selection of the right type of fluid, and understanding the manometer’s working principle are essential for optimal performance and protection.